PRODUCTS

PRODUCT CENTER

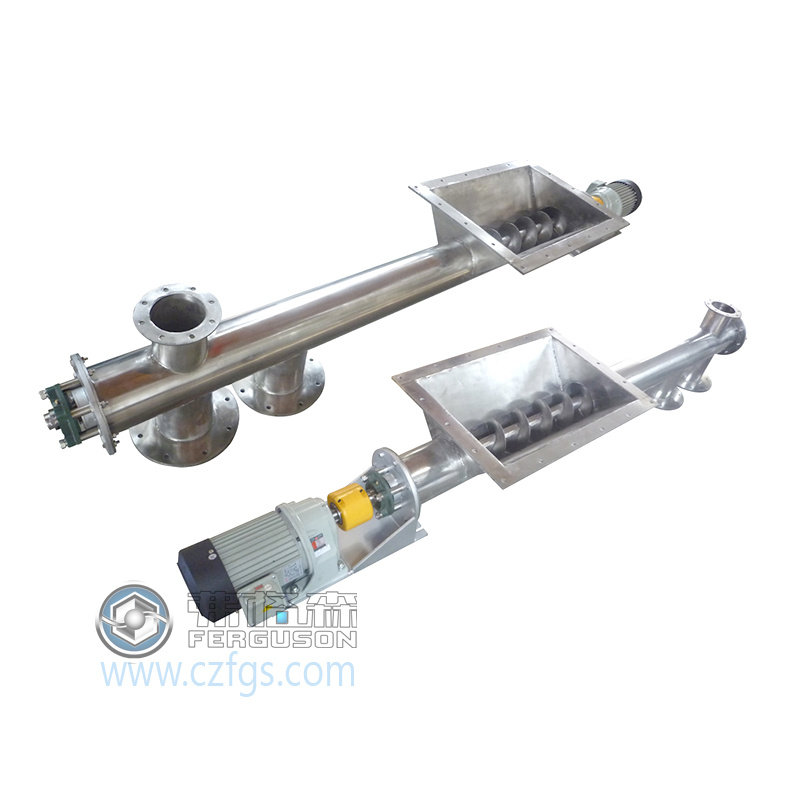

Pipe chain combination two

Category: Plate chain tube chain machine

Product Description:

Tubular chain conveyor (abbreviated as tube chain) consists of a closed-loop tubular shell, an internal closed-loop chain and a disc fixed on the chain, driven by the sprocket, and the disc drives the material to move when it rotates, so as to achieve the purpose of material transportation. The chain is used as a universal joint, so it can change the direction when moving, and it can be arranged flexibly. It is a fully enclosed conveying system, and it is completely dust-free during operation.

Carbon steel and stainless steel are optional, and explosion-proof, water-cooled, and nitrogen-protected types are available

Pipe chain conveyor features:

1. The structure of the pipe chain conveyor is simple and compact, and can be arranged horizontally, vertically, curved or three-dimensionally.

2. The pipeline can be fully enclosed for transportation, no dust leakage, high efficiency and environmental protection.

3. The pipe chain has the lowest energy consumption and lower operating costs.

4. Less maintenance, low maintenance cost and long service life.

5. The running speed is slow, which can ensure the integrity of the material to the greatest extent.

6. Explosion-proof design and airtight design can be realized.

Application advantages

1. According to the working conditions, it is possible to feed materials at multiple points and discharge materials at multiple points to realize a set of pipe chains, feed materials at multiple points, and discharge materials at multiple points.

2. The conveying raw materials are always in a closed state to ensure that no dust leaks into the environment.

3. There is no need to install a dust collector at the outlet, just a simple exhaust.

4. The conveying material is smoothly conveyed forward along the pipe between the two discs, basically without friction, so the material is less damaged, and the slow curve conveying makes very little material broken.

5. The management conveyors all adopt specially customized conveying discs, which have extremely low friction coefficient, high wear resistance and stable conveying.

Pipe chain conveyor components:

| name | Pipe chain chain plate | Motor box | Tension box | right angle wheel | sprocket |

| shape |  |

|

|

|

|

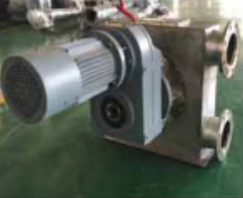

| illustrate | ● 16MN chain, 304 chain ● Plastic alloy chain plate, wear-resistant ● Self-locking bolts |

● Variable frequency speed regulation ● Guomao (equal brand) F series motor reducer ● Stable and noiseless operation |

● Contains spring tensioning device ● Contains sprocket ● Proximity switch is installed inside to protect the chain in abnormal conditions ● Patent number of sprocket tensioning device: 201620644140.7 |

● Bearing with seat, easy to disassemble ● Arc design, less residual material ● Reducing diameter design of inlet and outlet to protect plastic chain plate |

● Integrated casting ● High strength ● Beautiful appearance ● Patent No. of sprocket: 201620643198.X |

Performance parameters:

| Pipe Chain Conveyor _ |

model | Pipe chain diameter (mm) |

Delivery capacity (t/h) |

Conveying distance (m) |

power (kw) |

| TCC100 | DN100 | 4-8 | 0~60 | 0.55-4 | |

| TCC125 | DN125 | 5.5-11 | 0~60 | 1.1-5.5 | |

| TCC150 | DN150 | 8-16 | 0~60 | 2.2-7.5 | |

| TCC200 | DN200 | 15-30 | 0~60 | 3-15 | |

| TCC250 | DN250 | 25-50 | 0~60 | 5.5-18.5 | |

| TCC300 | DN300 | 34-64 | 0~60 | 7.5-22 |

Uses and application areas

1. Fine chemicals: pigments, dyes, coatings, carbon black, titanium dioxide, iron oxide, ceramic powder, heavy calcium, light calcium, bentonite, molecular sieve, kaolin, silica gel powder, activated carbon, etc.

2. Pesticide ore: urea, ammonium chloride, ammonium bicarbonate, soda ash, solid pesticide, tungsten powder, pesticide auxiliaries, copper concentrate powder, coal powder, phosphate rock powder, alumina powder, etc.

3. Building materials: cement, pottery, yellow sand, quartz sand, clay powder, silica, limestone powder, dolomite powder, wood powder, glass fiber, silicon dioxide, talcum powder, etc.

4. Food industry: flour, starch, grains, milk powder, food additives, etc.

Previous Page

Next Page

RECOMMENDED PRODUCTS