PRODUCTS

PRODUCT CENTER

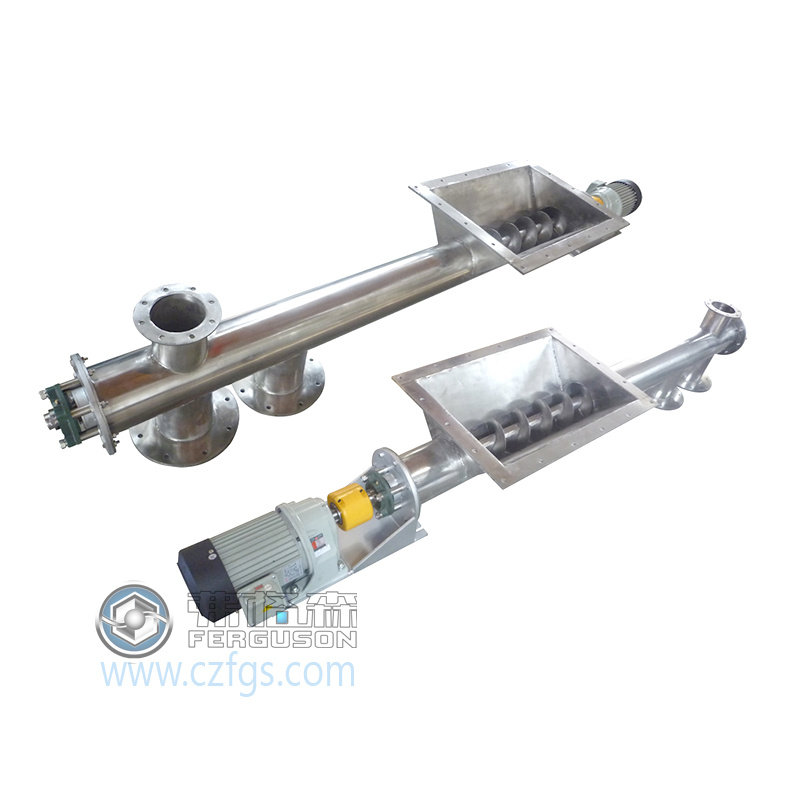

Jacket (water-cooled) spiral

Category: Screw conveyor

Product description

Screw conveyor is a kind of mechanical conveying equipment widely used in metallurgy, electric power, chemical industry, building materials, food and other industries. It is mainly used to convey powder, small particles and small block materials, and it can be horizontal and inclined. It has simple structure, small cross-sectional area, low cost, convenient operation, flexible layout of inlet and outlet positions, and can meet the technological requirements of multi-point feeding and multi-point discharging.

Carbon steel and stainless steel are optional, explosion-proof, water cooling, heating, and nitrogen protection can be customized.

Structural features

The operating environment of the ordinary screw conveyor is -20℃~50℃, the material temperature is ≤50℃, the conveying inclination angle is ≤45℃, and the conveying length is ≤40m. When the conveying distance reaches 40m~70m, the double-end drive type can be adopted. The head and tail bearings are arranged outside the shell, and the seal between the shaft and the shell adopts a packing structure; the intermediate suspension bearing adopts two structural types that can be interchanged with rolling and sliding; the screw conveyor generally uses one-way conveying materials, which can also be realized Two-way transportation of materials.

Technical parameters of screw conveyor

| Spiral diameter (mm) | 160 | 200 | 250 | 315 | 400 | 500 | 630 | 800 |

| Pitch (mm) | 160 | 200 | 250 | 315 | 355 | 400 | 450 | 500 |

| Speed (r/min) | 112 | 100 | 90 | 80 | 71 | 63 | 50 | 40 |

| Conveying capacity (m3/h) | 8 | 14 | 24 | 34 | 64 | 100 | 145 | 208 |

| Rotating speed(r/min) | 90 | 80 | 71 | 63 | 56 | 50 | 40 | 32 |

| Throughput(m3/h) | 7 | 12 | 20 | 26 | 52 | 80 | 116 | 165 |

| Rotating speed(r/min) | 71 | 63 | 56 | 50 | 45 | 40 | 32 | 25 |

| Throughput(m3/h) | 6 | 10 | 16 | 21 | 41 | 64 | 94 | 130 |

| Rotating speed(r/min) | 50 | 50 | 45 | 40 | 36 | 32 | 25 | 20 |

| Throughput(m3/h) | 4 | 7 | 13 | 16 | 34 | 52 | 80 | 110 |

Previous Page

Next Page

RECOMMENDED PRODUCTS