Automatic unpacking of tonnage

PRODUCT CENTER

Automatic unpacking of tonnage

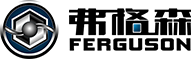

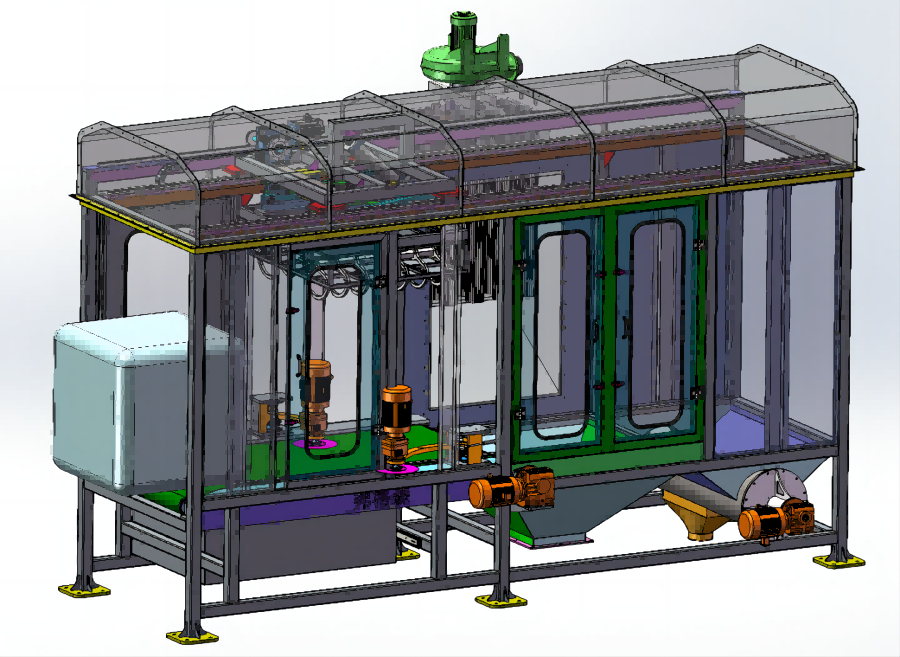

The fully automatic unpacking machine, also known as the automatic bag breaking and unloading machine, is used for the unpacking and unloading of bagged powder and granular materials. It uses a belt conveyor to automatically feed the bag, a cutting knife device to automatically break the bag, a vibrating screen to automatically separate and discharge the bag material, and other steps. The material falls into the storage hopper by gravity to complete the bag removal and unloading work. The dust generated during the operation is filtered out by the carried dust removal device, enabling workers to work in a clean environment. Mainly used in the production fields of petroleum, chemical industry, medicine, food, chemical fiber, electricity, building materials, environmental protection, metallurgy, etc., for automatic unpacking and unloading of dry powder materials, such as nitrate lime, magnesium oxide, quartz sand, limestone, sawdust, protein powder, activated carbon, milk powder, PVC powder, fly ash, urea, clay, gypsum, cement, sewage treatment adding powder, etc. can all be automatically unpacked and unloaded. It can be linked to DCS for remote control. The fully automated dust-free unpacking working environment has been achieved, which not only improves production efficiency but also effectively protects the environment.

The fully automatic unpacking machine is efficient, environmentally friendly, easy to operate, and easy to maintain. When used in conjunction with other conveying equipment, it can complete bag breaking unloading and powder conveying and storage. The fully automatic unpacking machine has the characteristics of reliable operation and low power consumption, which is particularly suitable for toxic, flammable, highly corrosive, high dust, and places where personnel are not easily exposed. The automatic bag breaking and unloading machine is used for bag breaking and unloading of powdered and granular materials. In the fields of chemical engineering, petroleum, building materials, metallurgy, electricity, food, medicine, grain, environmental protection, and other fields, dry powder materials can be automatically unpacked and unloaded, such as nitrate lime, magnesium oxide, quartz sand, limestone, sawdust, protein powder, activated carbon, milk powder, PVC powder, fly ash, urea, clay, gypsum, cement, sewage treatment and adding powder. It can be automatically bagged and unloaded through a belt conveyor, The cutting device automatically breaks the bag, and the vibrating screen automatically separates and unloads the bag material. The material falls into the storage hopper by gravity to complete the bag removal and unloading work. The dust generated during the operation is filtered out by the carried dust removal device, enabling workers to work in a clean environment. This equipment is efficient, environmentally friendly, easy to operate, and easy to maintain. When used in conjunction with other conveying equipment, it can achieve functions such as unloading broken bags and conveying and storing powder. The automatic bag breaking unloader has the characteristics of reliable operation and low power consumption, and is particularly suitable for toxic, flammable, highly corrosive, high dust, and places where personnel are not easily exposed. The automatic bag breaking unloading machine includes: 1. Belt conveyor 2. Cutting blade device 3. Vibrating screen 4. Shell 5. Bracket 6 Dust removal device 7. Conveyor 8. Electric control box.

The automatic bag breaking machine equipment is widely used in major factories, chemical, plastic, sewage treatment, mechanical development bases, and other industries during use. The equipment does not leak any dust during the bag breaking process, effectively protecting the environment and working space. Workers can work in a better environment, which is beneficial for their physical and mental health.

After the automatic bag breaking machine breaks the bag, there is no residual material in the residual bag, which can avoid material waste and can be recycled into recycled materials due to the cleanliness of the residual bag. After the bag is broken, there are no impurities in the output material. This device also has the characteristics of low power consumption, low noise, light weight, and low failure rate.

Physical Case

Automatic unpacking of tonnage

Automatic unpacking of tonnage

Automatic unpacking of tonnage