Solutions

Solutions

Physical Case

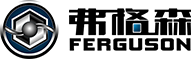

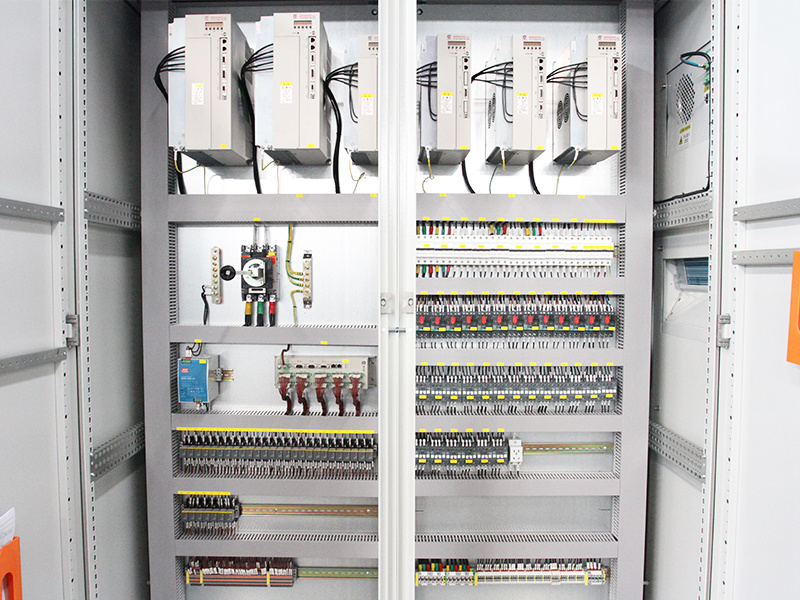

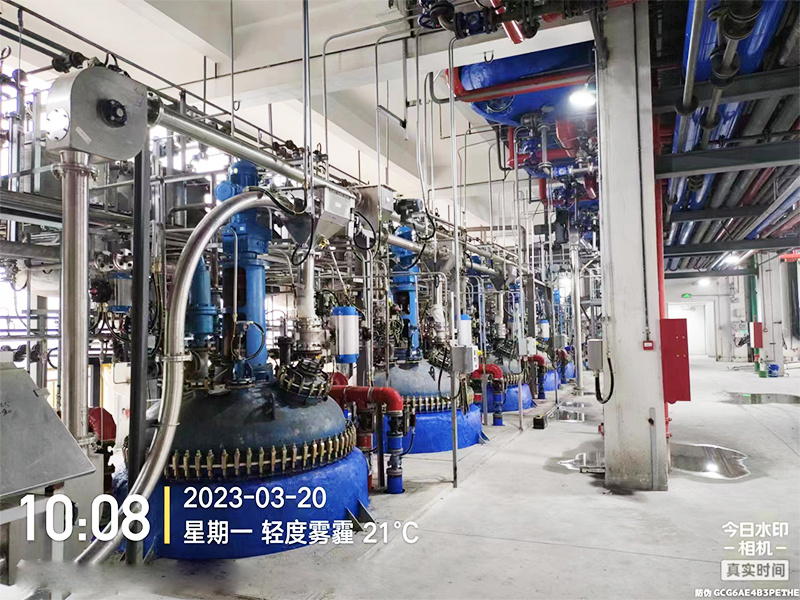

Intelligent production manufacturing

Intelligent production manufacturing

Intelligent production manufacturing

Automatic weighing of ingredients

Automatic weighing of ingredients

Automatic weighing of ingredients

Dust free unpacking and material preparation

Dust free unpacking and material preparation

Dust free unpacking and material preparation

Pipe chain conveying system

Pipe chain conveying system

Pneumatic conveying system

Pneumatic conveying system

Pneumatic conveying system

Contact Information

Contact person: Mr. Sun +86-13515269469(Wechat)

E-mail:sun@czglzz.com

Contact person: Mr. Li +86-13815051091(Wechat)

E-mail:lj@czglzz.com

Tel: 0086-519-83867299

Web: www.czfgs.com

Address: No.58 Songtao Road, Zhonglou District, Changzhou, Jiangsu Province, China

Online Message