Automatic unpacking of small packages

PRODUCT CENTER

Automatic unpacking of small packages

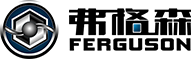

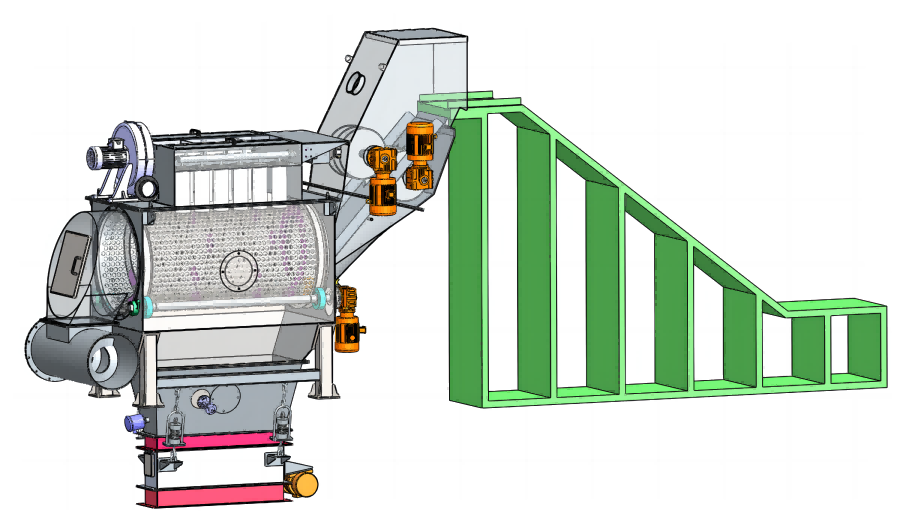

The small bag automatic unpacking machine, also known as the small bag automatic dust-free feeding station, refers to the entire production process as long as the small bag packaging materials are placed on the conveyor belt, and the rest is automatically carried out by the unpacking machine. During the entire unpacking process, the filter and dust removal fan are used to remove dust, and the dust will not leak out. It is suitable for 10-50KG small bag packaging powder particles Comprehensive control of dust during the pouring process can be carried out.

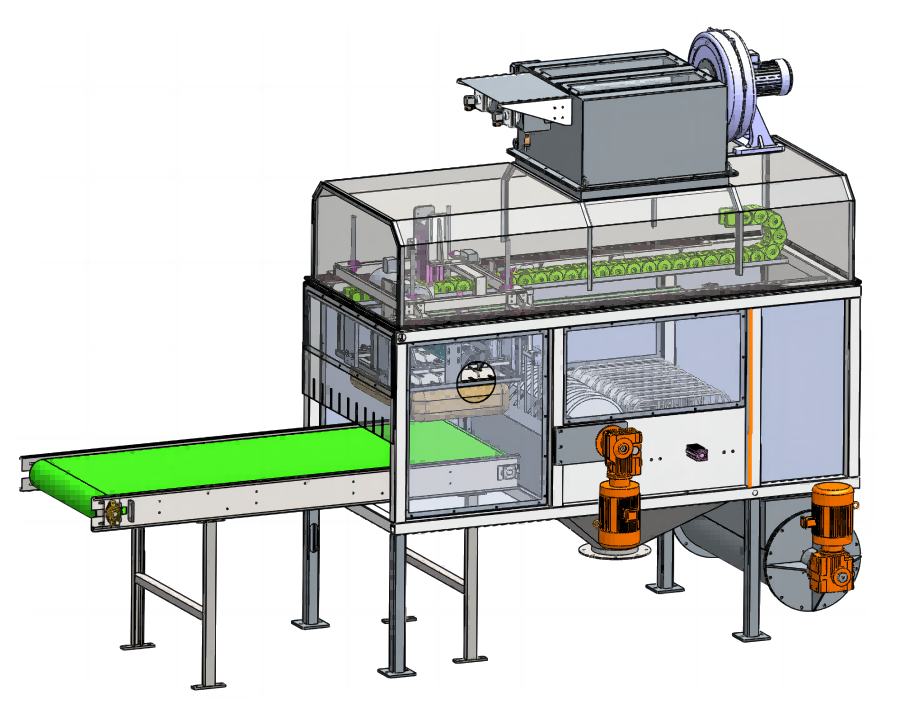

This dust-free dumping station equipment is a combination, and the automatic unpacking machine consists of seven parts: belt conveyor, cutting blade device, drum screen, intermediate bracket, bag dust collector, screw conveyor, and control box. Collect the dust raised during unpacking through a fan, and filter and purify the dust before reaching the standard for discharge.

Technical features

1. The material is completely enclosed during the process of bag breaking and material separation, and each process is equipped with a dust collection device, which ensures no dust leakage and low noise, improving the working environment for workers.

2. Only one to two people need to place the packaging bags on the belt conveyor on site, reducing the workload of workers.

3. The equipment is easy to operate, reliable, and has a low failure rate, reducing maintenance workload.

4. The equipment has been specially designed to separate broken packaging bags from the materials and will not be mixed into the materials or hung in the separation device.

5. After bag breaking, unloading, and separation, it can be used in conjunction with other conveying equipment to complete functions such as powder conveying and storage.

6. You can handle packaging bags of different sizes without adjusting the equipment.

7. The equipment is equipped with dust removal function, and there is no dust flying during the bag opening and material pouring process.

8. The unpacking machine can also be used as a supporting equipment, which can be transported to downstream devices through screw conveyors, pipe chain conveyors, or pneumatic negative or positive pressure conveying systems.

Note: Due to changes in material properties, usage scenarios, and discharge methods, the configuration, output, materials, and power of the entire equipment of the automatic unpacking machine may vary.

Scope of use

Automatic unpacking machines are widely used in fields such as chemical engineering, petroleum, building materials, metallurgy, electricity, food, medicine, grain, and environmental protection. For example, nitrate lime, magnesium oxide, quartz sand, limestone, sawdust, protein powder, activated carbon, milk powder, PVC powder, fly ash, urea, clay, gypsum, cement, and sewage treatment adding powder can all be used for automatic unpacking and unloading operations.

Ferguson, as a research and development manufacturer of unpacking machines, also has small bag feeding stations, layer by layer unpacking machines, ton bag feeding stations, and ton bag unpacking machines.

Physical Case

Automatic unpacking of small packages

Automatic unpacking of small packages